Products

SWS Step Saver

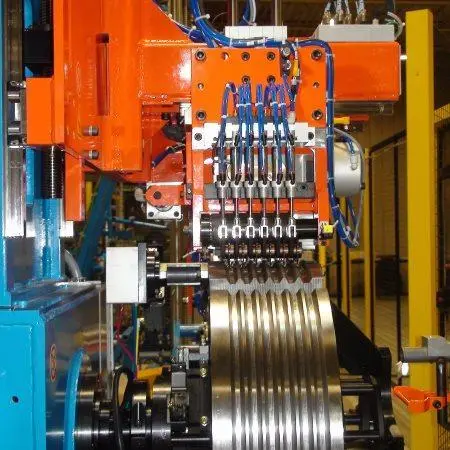

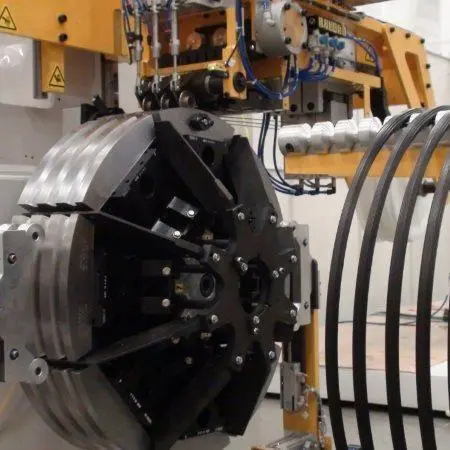

Bartell now offers a completely new bead manufacturing product line for the tire industry, the SWS-Thousand Series Step Saver System. Designed and engineered to solve the high variation, low volume, productivity problems by enabling tire manufacturers to easily switch bead sizes without wasting valuable run-time associated with changing from one bead diameter to another. The formers that are fit for this machine have two or three different diameters, or bead profiles, per set, allowing an automatic change from one bead size to another. Not only does this increase your production, it also eliminates downtime associated with switching tooling, removing any chance of operator error during that procedure. Backed by Bartell’s world class quality and 24/7 parts and service availability, the Step Saver System is the ultimate answer to exceptional productivity in the high variation world that is tire manufacturing today. This bead winder can be part of either our SWS or Festoonless Single Wire Bead Lines and will accommodate all machine options.

- Two or Three diameters (bead profiles) on one former

- Automatic change-over from one size to another

- Change-Over Time is Less Than 60 Seconds

- Eliminates operator error

- Ability to produce passenger and truck tires

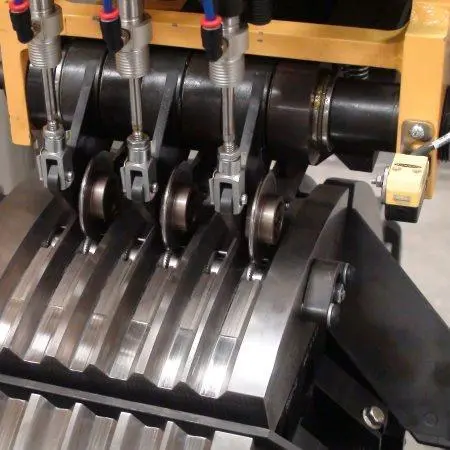

- Servo-actuated wire advance

- Sensors detect individual wire pull-outs for better troubleshooting and maintenance

- 0° – 15° flat or taper base bead

BEAD PARAMETERS

Bead ID: 13.00 – 25.00” (330 – 635 mm)

Bead Width: 1.3125” (33.3 mm)

Bead Height: 0.75” (19 mm)

Bead Base Angle: 0 Deg – 15 Deg

BEAD CONSTRUCTION

Individual Diameter Adjustment: + / – 0.125”

Step Diameter Adjustment: 5” Maximum

Shape: Hexagonal, square, offset

Cross-over: Single or multiple point

PRODUCTION CAPABILITIES

Beads per cycle: Two (2) or Three (3)

Line Speed: 450 ft/minute (304 m/minute)

Change Over Time: Less than 30 seconds

Productivity (2 beads):

15” (381mm) 19-turn @ 4.2 beads/min

15” (381mm) 19-turn @ 2,016 beads/8 hour shift

22.5” (571.5mm) 65-turn @ 1.2 beads/min

22.5” (571.5mm) 65-turn @ 576 beads/8 hour shift

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.