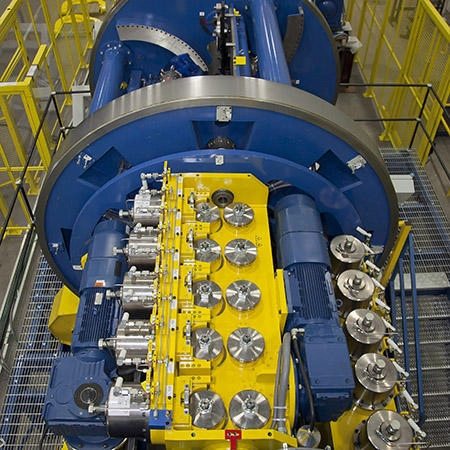

Pressure Armouring/Flexlock Machines

This machine is built to wind and interlock, steel “Flexlock” pressure armouring strips in long lengths on a flexible tube in a continuously wound helix for use in high pressure flexible pipe applications. It is capable of winding two or four shaped strips on a pitch diameter range of 60-500 mm so that they interlock to form a flexible barrier against fluctuating high pressure changes within the pipe.

The cage is designed to receive two (2) or four (4) bobbins each of a maximum load 9,000 kg. The rotary cage has a horizontal axis with the maximum product passage through the cage being 500 mm and is supported at one end by a large bearing assembly and at the other end, via two (2) sets of trunion wheel assemblies. The tooling assembly is mounted at the exit of the cage to suit the various pipe sizes and armouring material shapes used. Loading of the cage is by overhead crane and the maximum cage speed is 50 RPM with a maximum reversing cage speed of 1-10 RPM.

Specifications

Product O.D.: 60 mm – 500 mm

No. of Payoffs: 4 x Payoff for 1200 mm bobbins

Bobbin Size: 1200mm Flange x 610mm Drum x 1500mm Wide

Max Load: 9,000 Kg gross, 1200 mm OD bobbin

Max. Passage: 560 mm

Product Weight: 400 kg/m

Max. Cage Speed: 50 rpm

Max. Reversing Cage Speed: 0 – 5 RPM (normal operation)

Machine Direction: Right to Left

We offer custom built systems beyond specifications listed here, please contact a Bartell Sales Representative to discuss your requirements.

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.