Products

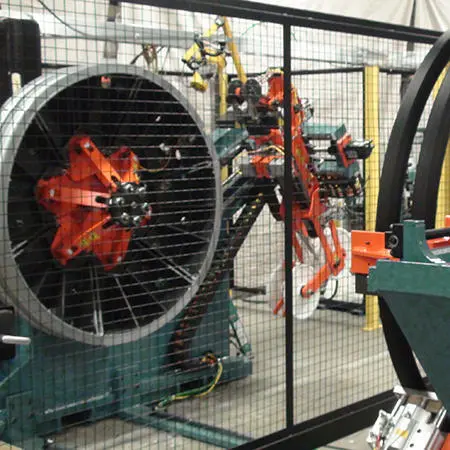

DUAL GIANT

The single wire bead system revolves around a rubber coated single wire, that is wound around a fixed diameter former and stepped to lay side-by-side upon completion of each convolution, forming a layer. This machine is able to produce beads ranging from 24” (600 mm) to 72” (1825 mm), with the ability to produce almost any shape bead, with hexagonal being the most common.

Engineered to produce beads with optimum utilization of bead wire properties, the Dual Giant Bead Winding System is a fully integrated bead line controlled through a Programmable Logic Controller (PLC), incorporating a twin access servo drive for step control. Bead profiles of up to forty (40) wires wide and forty (40) layers high can be produced with cross section shapes of practically any size.

The Dual Bead Winder System consists of the following:

- A Dual Bead Winder constructed from a machined steel body which houses both the “former” and “pay-on” drive motors (AC brushless servos). The winder is capable of accepting various bead profiles producing beads ranging from 24” (600 mm) to 72” (1825 mm) in diameter. Operation is semi-automatic, requiring a manual unload after each cycle has been finished. The formers are adjustable by ± ¼” (6 mm) of nominal diameter.

- A 2 1/2” Coldfeed Plastiscrew Extruder controlled by an AC variable speed drive, and fitted with a patented “venting” insulating head. Extruder temperatures of the extruder head, barrel, and screw, are regulated through a three (3) zone electric/water control arrangement. The extruder contains a loss of rubber proximity switch, notifying the operator if there is a loss of rubber, or break in the feed.

- Let-Off equipment is comprised of Two Power-Driven Heavy-Duty Let-Off Stands, capable of accelerating or decelerating the reels of wire to match winder speeds. These units are complete with low reel sensors and wire break proximity switches.

- The complete system is protected via a simple perimeter fence having an electrically interlocked entry gate at the let-off position for access for machine set-up and reel change-over operations.

- A user friendly Operator Interface Terminal

- Wide Range of Bead Diameters

- Optional Distributed Cross-Over Improving Bead Uniformity

- Compact Design Reduces Floor Space Requirements

- Footprint – 20’ L × 12’ W × 9’ H (6 m L × 3.75 m W × 2.75 m H)

- Simple String-Up and Change-Over Procedures

- Integrated Control System Decreases Operator Error

Maximum Line Speed of 750 ft/min (228.6 m/min)

Bead Internal Diameter 24” – 72” (600 mm – 1825 mm)

Bead Width (max) Up to 40 wires or 3.75” (95 mm)

Bead Height Up to 40 wires or 3.75 “ (95 mm)

Bead Base 0° – 15° taper base

Beads per Cycle 2 Max.

Diameter Adjustment ± ¼” (6 mm)

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.