Products

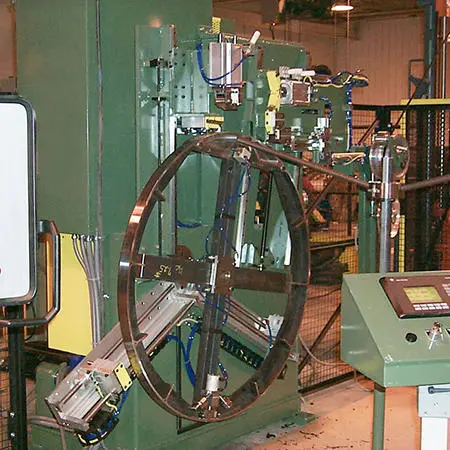

TDS-980

The TDS-980 construction makes it ideal for a stand-alone replacement of your existing weftless winder as well as an integral part of a whole new bead system. The TDS-980 capabilities include :

- Nominal Bead Range -Either 4″to 30″ (100 -762mm) or 30″ to 60″ (762 -1524mm).

- Maximum Ribbon Width of 1.25″ (31.75mm)

- Programmable Bead Overlap Length

- Single, Dual, Triple or Quad Bead Production

This machine is developed for continuous production of high quality beads, low operator involvement and speed of changeover, the Bartell TDS-980 uses state-of-the-art technology to meet today’s challenges.

The TDS-980 System consists of the following:

- A TDS-980 Bead Winder automatically produces either 1,2,3 or 4 weftless beads per machine cycle. The winder is complete with a servo driven former assembly for precise speed and position control and a Programmable Logic Controller (PLC) for control of the automatic cycle.

- A pneumatic festoon unit interfaces the stop/start action of the winder with the more constant insulating process of the extruder. The pneumatic festoon uses a cable cylinder to pretension the wires. The lower sheave assembly travels up and down the masts using linear guide rails. A transducer on the festoon mast controls the wire tension and safely stops the winder. Another unique feature is that by raising the lower sheave assembly, the top sheave assembly may be released from its safety latch for easy string-up at floor level.

- A Bartell/RMS Cold Feed Plastiscrew Extruder complete with Temperature control Units and the Bartell insulating head.

- Let-Off Equipment consisting of up to 24 Heavy Duty Let-Off Stands, a multi-station gathering rail and a guide roll stand.

- Integrated Control System, including PLC and Servo system drives and motors, for automatic control of the process.

- Operator Interface Terminal containing menu screens, run screens, manual screens and diagnostic screens.

- We strongly recommend as original equipment, electrically interlocked perimeter guarding designed and integrated by Bartell.

-

Feature Benefit Single Operator ControlMinimal Manpower RequirementWide Bead Diameter RangeProduction FlexibilityIntegrated Line ControlControlled ProcessMulti Bead Recipe StorageReduced DowntimeAutomatic Bead EjectContinuous ProductionSimple Machine Set-upReduced DowntimeRadial Expand FormerMulti Size Bead DiametersHigh Bead ProductivityReduced Bead Cost

BEAD ID

10″ – 25″ (250mm – 635mm)

BEAD CONVOLUTIONS

2 – 20 turns or 1.0″ (25.4mm)

BEAD CONSTRUCTION

Diamater Range: -0.250″ / +0.750″

Diameter Adjustment: Accomplished via wedge block

Shape: Square, rectangular

BEADS/CYCLE & BEAD WIDTH

Single – 1.250″ (32mm)

Duals – 0.625″ (16mm)

Triples – 0.417″ (11mm)

Quads – 0.303″ (7.6mm)

TOOLING PARAMETERS

Feed Tray Width (max): 1.750″

Former Gripper width (max): 1.750″

Former width (max): 1.750″

PRODUCTION CAPABILITIES

Bead per cycle: 1-4

Productivity: 14″, 4T, 2″ O.L. @ 18 cycles/min. e/eject

Line Speed: 500ft/min (150m/min)

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.