OIL & GAS

We deliver industry-leading manufacturing solutions for critical onshore and offshore oil and gas systems using advanced technologies that enable customers to innovate and expand the boundaries of oil and gas discovery.

Oil & Gas

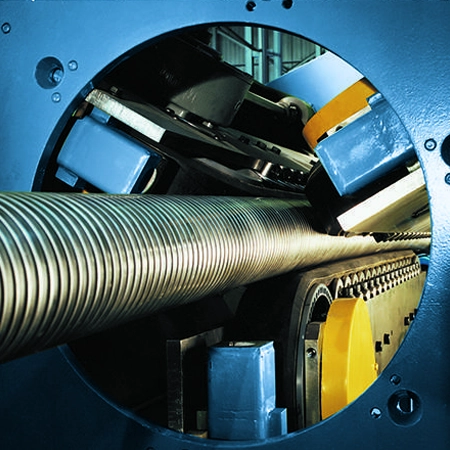

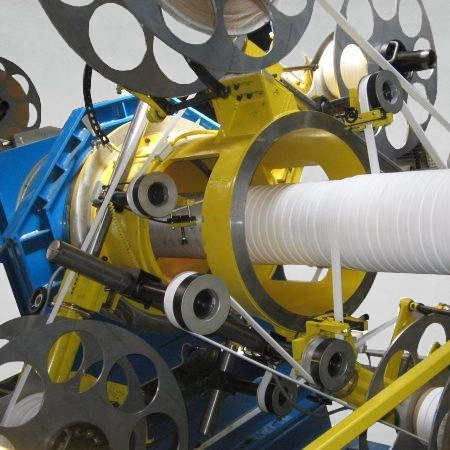

Bartell has designed and built some of the world’s largest systems for Tensile Armouring, Pressure Armouring (Flexlock), and Carcass Production, delivering unmatched quality for critical systems. Through our dedicated research and development of manufacturing systems, we have enabled the production of subsea flexibles for extreme ocean conditions, at depths up to 3,000 meters.

As we continue to develop systems for onshore material handling and offshore deployment, our focus is to deliver cutting-edge technologies allowing customers to create solutions that meet the ever-expanding envelope for the discovery of oil and gas.

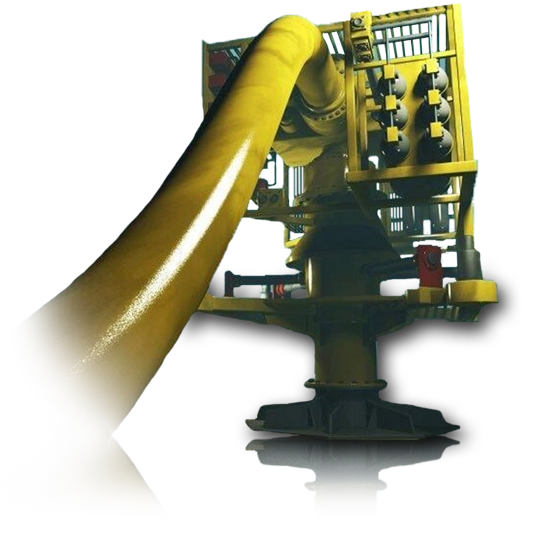

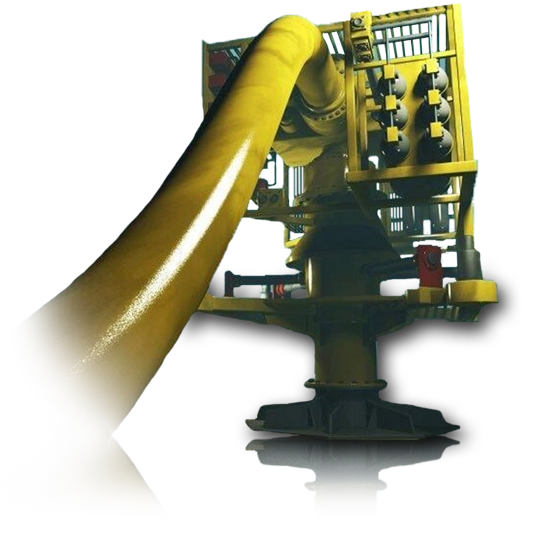

Bartell offers a wide variety of tensioners for several applications within the oil and gas industry. These units are designed and engineered to meet demanding customer requirements associated with a broad range of pipe designs. The tensioners can be either chain or cleat type, containing three (3) or four (4) track assemblies.

Bartell’s armouring lines allow manufactures to design and produce the most advanced configurations of flexible pipe with the most advanced materials at the highest quality and productivity standards.

Various applications within the wire and cable and oil and gas industries require that elements be insulated or shielded to meet the standards and demands of specific applications. Taping heads are available in 2-pad, 4-pad, and bobbin configurations. These units can be integrated into new or existing production lines or staged as stand alone for offline processing.

Under rollers are used in a variety of applications in which the onshore pay-off and take-up various lengths and diameters of flexible offshore pipe or umbilical cables is desired. Bartell offers under rollers ranging in size from 30 Tonne to 500 Tonne capacities.

Industries

Flexibility, corrosion resistance, extreme pressure and tensile loads.

The critical link to the operation, control and delivery of energy resources.

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.