ABOUT US

ABOUT US

Where some see challenges we see the opportunity for innovation. Since our founding in 1940, Bartell has continuously worked to develop leading manufacturing solutions for a variety of industries. With generations of industry knowledge and engineering experience coupled with our world-class sales and technical service network, Bartell continues to deliver state-of-the-art technologies capable of meeting the most advanced production needs.

Guiding Principles

INTEGRITY – CONTINUOUS IMPROVEMENT – INNOVATION – EMPLOYEE FOCUS – SAFETY – QUALITY

A Quick Look at Bartell

- Headquartered in Rome, New York, U.S.A, with additional locations in the United Kingdom and China

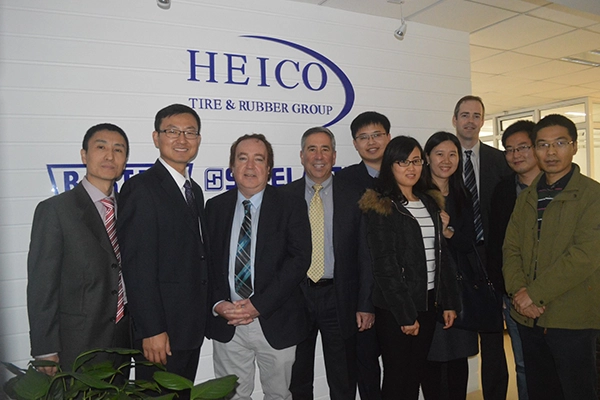

- A member of The Heico Companies Inc. which consists of over 45 high tech and industrial manufacturing companies

- An ISO 9001:2015, ISO 14001, ISO 45001 and OSHA V.P.P Star certified company

- A dedicated 8,600 square foot R&D facility

- 140,000 square feet of production space for equipment design, manufacturing, and testing

- 24/7 Technical Support

- Bartell has delivered over 8,500 machines worldwide

HISTORY TIMELINE

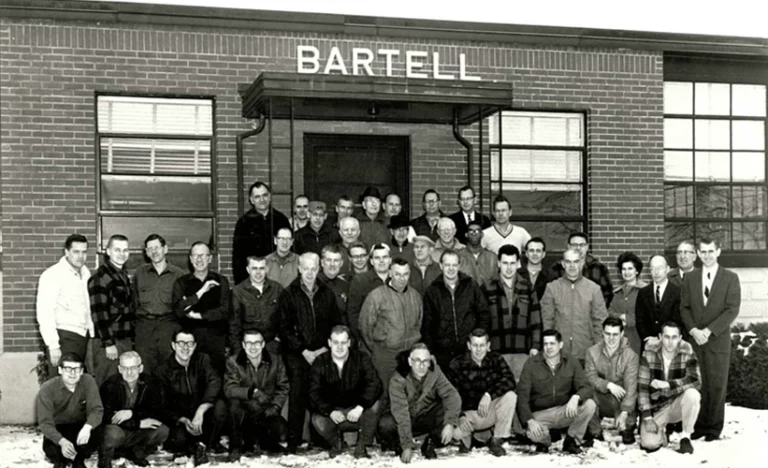

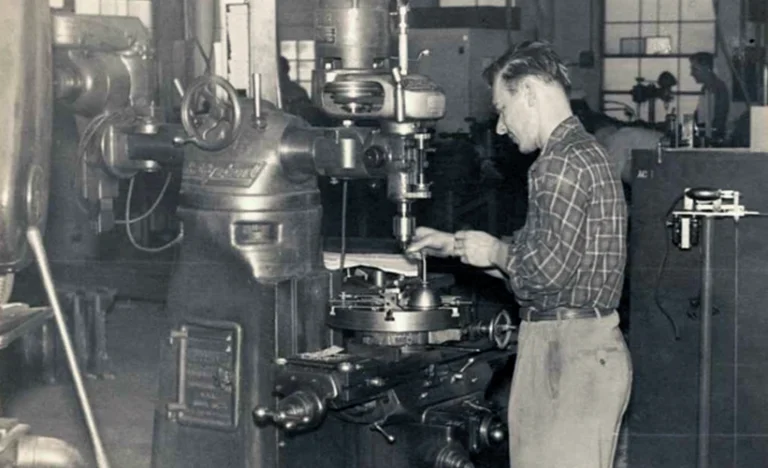

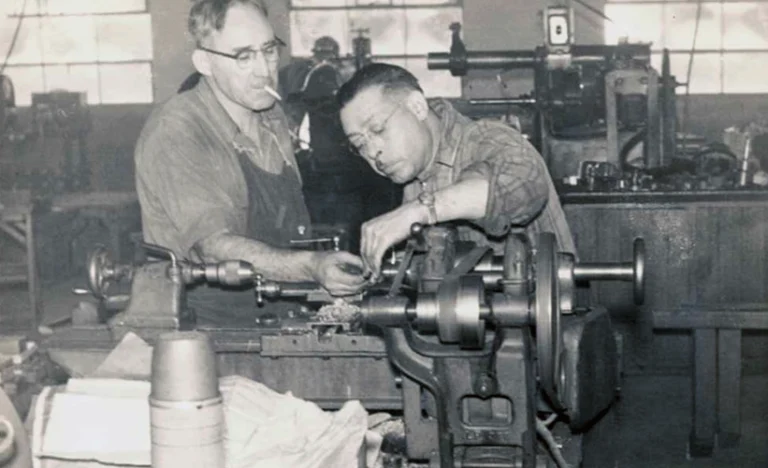

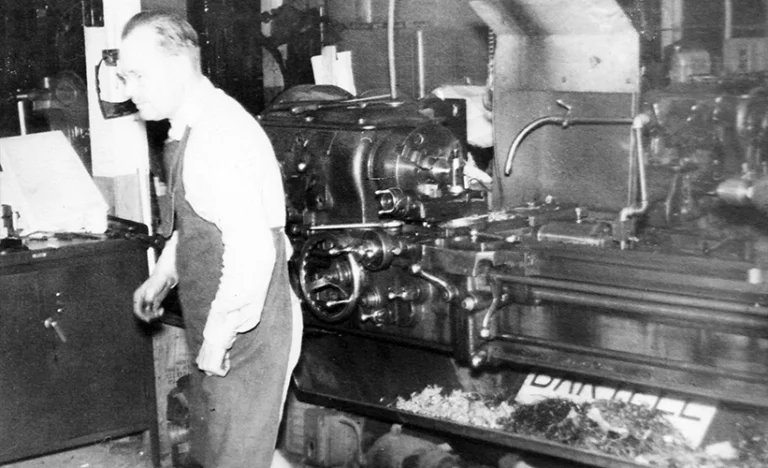

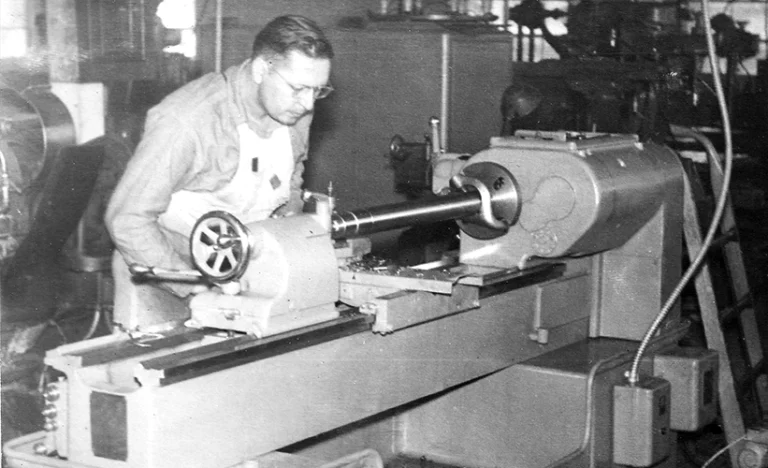

Bartell is founded by Ernest J. Bartell as a precision tool and die shop to service the local wire, cable, and other manufacturing industries in Rome, NY.

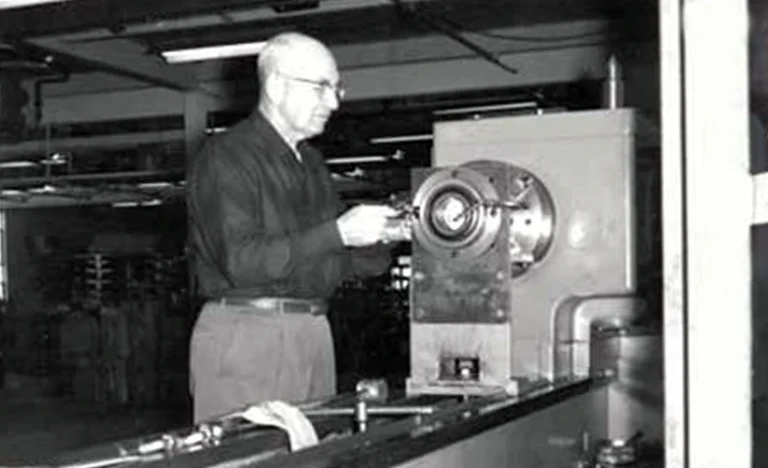

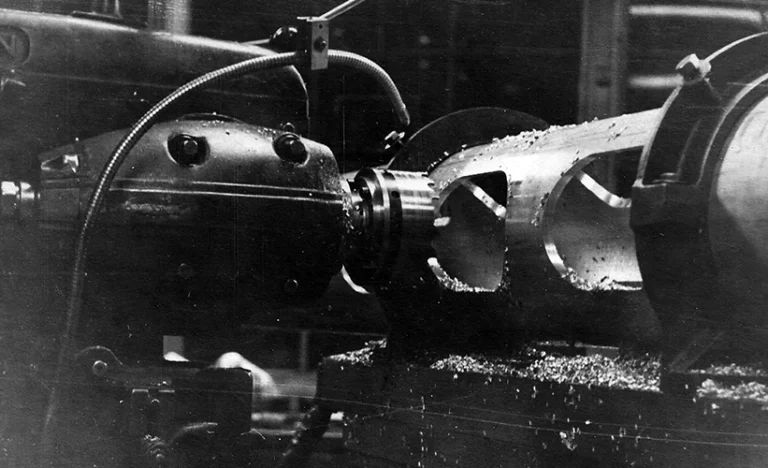

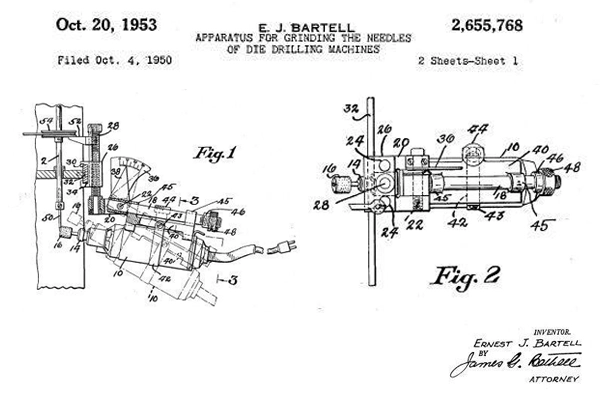

Mr. Bartell was awarded the companies first patent for an “apparatus for grinding the needles of die drilling machines”. This innovation allowed for the simplification of the process of grinding needles in die drilling machines without removal leading to improved productivity.

Bartell is purchased by National Standard Co. allowing Bartell to expand operations into the tire component industry.

Bartell develops and releases its first single wire bead winding system.

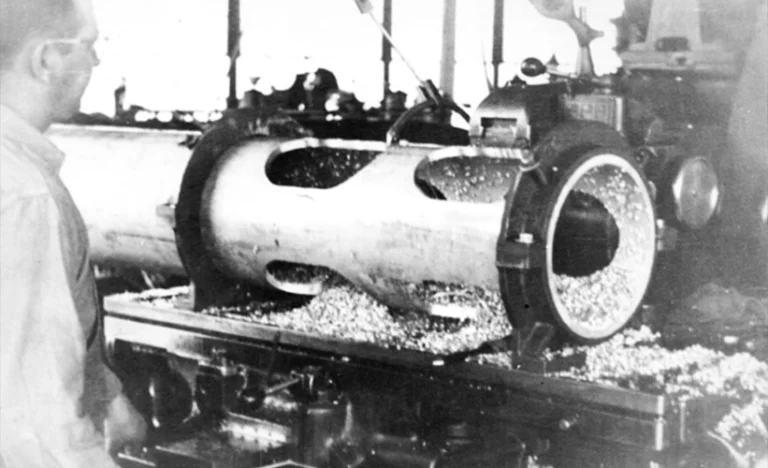

CEECO (now Bartell) develops its first Carcass machine for the production of the inner layer flexible pipe applications in the oil and gas industry.

Company was repurchased by the Bartell family.

Bartell opens sales and support office in Telford, U.K, to better service current and new customers in European markets.

Bartell joins The HEICO Companies LLC and becomes part of the Pettibone Equipment Group joining tire industry.

Bartell acquires CEECO, a leader in the production of wire and cable manufacturing equipment, integrating its rich history and innovative designs expanding the product portfolio of Bartell.

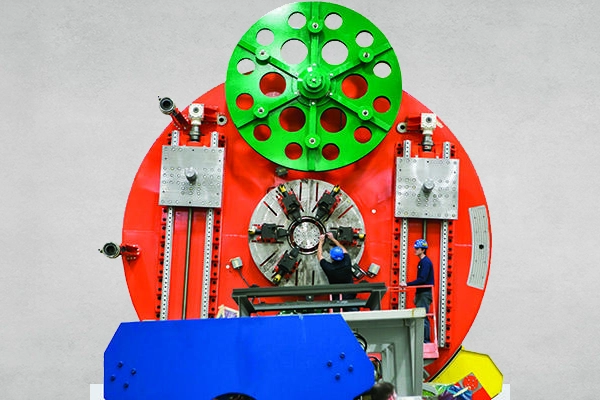

Bartell designs, manufacturers and delivers the worlds most advanced carcass manufacturing equipment for the production of deeps sea oil and gas pipe.

Qingdao, China opens to allow our Asia/Pacific customer to have regional access to sales, technical support, and world class service.

Bartell celebrates 75 years of growth and success.

Our Leadership Team

Providing our customers with the industry’s best manufacturing solutions drives our teams’ efforts in shaping our business. Bartell’s leadership philosophy empowers employees while creating dynamics strategies that provide a framework for continuous improvement, superior quality and advanced production systems. Leveraging decades of experience ensures that Bartell will continue to deliver; meeting our customers’ needs of tomorrow.

Engineering

Sales & Project Management

William Cacciapouti

UK Office

Ged Lee

Donna Allen

Joyce Evans