Products

- — Bow Cablers

- — Data Cabler

- — Data Group Twinner

- — Backtwist Twinner

- — High Speed Twinner

- — Single Twist Strander

- — Fiber Optic Planetary Strander

- — Aramid Fiber Strander

- — Ribbon Fiber Strander

- — Electrical Planetary Strander

- — Roll Forming Strander System

- — Tubular Strander

- — Rigid Strander

- — Drum Stranders & Cablers

- — OrbiStrander

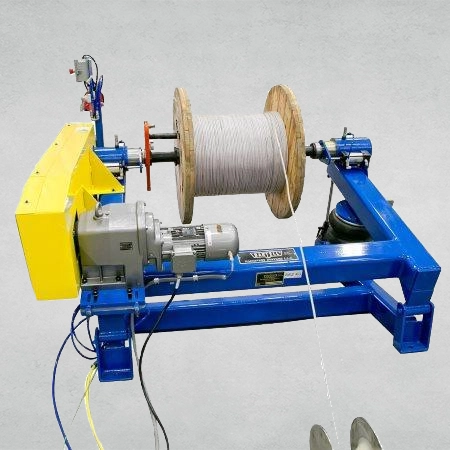

Shaftless Cantilever

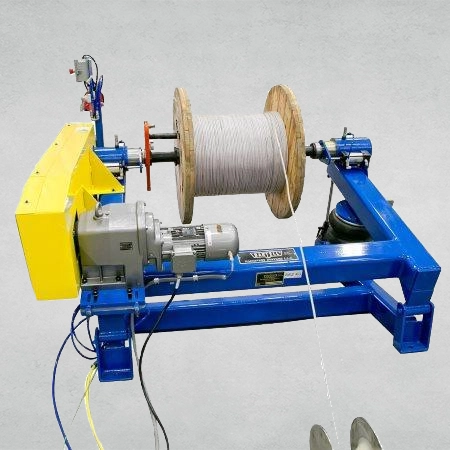

Built to be the toughest machines in the industry, Bartell take-ups and pay-offs are available in a wide range of sizes, weight capabilities, and tension ranges suitable for a variety of applications.

Our standard line of cantilevered lift-arm shaftless style takeups and payoffs operate with reels from 16 inches to 120 inches in flange diameters with weight capacities up to 40,000 lbs. Offered in both driven and non-driven configurations Bartell can provide a solution for the most demanding applications. If the configurations listed do not meet your requirements, please contact our sales engineering team to discuss how Bartell can customize a configuration to meet your needs.

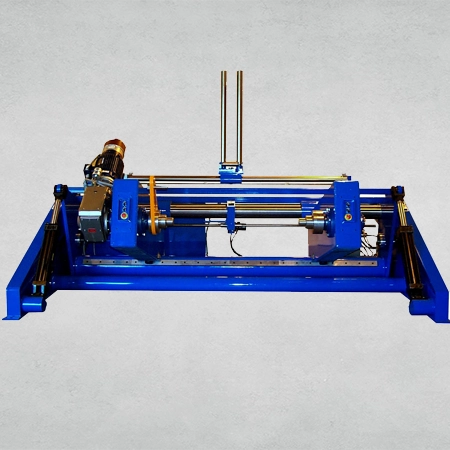

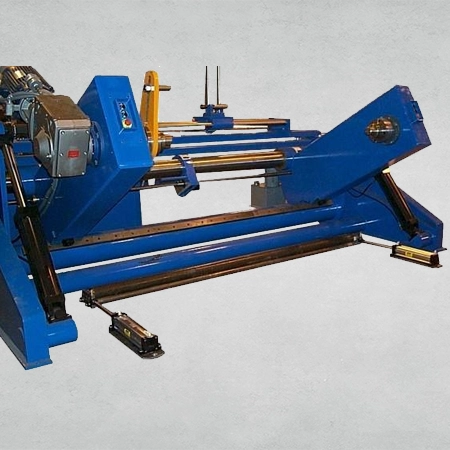

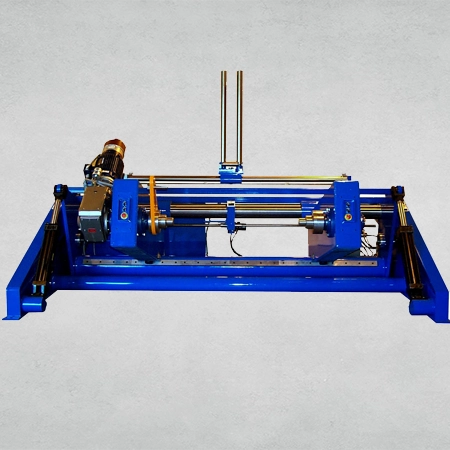

This configuration is constructed of a compact, rugged, steel fabricated base frame and a pivoting arm assembly complete with sliding pintles. Lifting and lowering of the reels are achieved through actuators mounted on steel support sections of the frame with self-leveling pintels.

Our drive train has been redesigned to directly couple the motor to the gearbox to the pintle shaft, eliminating the traditional transmission, drive shaft and chain drive. The improvements enable easier maintenance and less wear.

The traverse assembly is more stable, more accurate and more powerful than ever before. The traverse roller assembly uses linear ball bearing tracks and rails for more rigid travel. The traverse assembly utilizes a non-contact magnetic transducer to determine the location and turn around points, thereby eliminating mechanical adjustment of the traverse. The motor and gearbox have been designed to give better results for a quicker turnaround at flanges. The motor and gearbox have also been designed to allow a broader range of products to run at a broader range of speeds.

- Hydraulic Lift Design

- Standard fail-safe brake system

- Continuously welded heavy steel construction

- Customized tension capabilities

- Case hardened steel pintles

- Customized control panels

- Optional shuttling capabilities

- Operation in speed or tension mode

- Ability to integrate into new or existing process lines

- Standard dual horizontal arm drive-payoffs only

- Dual level braking (drag/tension and e-stop)-payoffs only

- Adjustable traverse opening-take-ups only

- Standard electronic traverse with pause/delay at flange (retrofit capability to existing take-ups and payoffs machinery)

The Bartell Standard Duty Cantilever configuration is suitable to accommodate reels up to 72 in flange diameter and is constructed of a compact, rugged, steel fabricated base frame and a pivoting arm assembly complete with sliding pintles. Lifting/Lowering of the reels is achieved through pneumatic airbags mounted on steel support sections of the frame with self-leveling pintles.

- Dual Horizontal Lift Arm with Complete pneumatic systems for positioning of the lift arms in the open, close, up, and down directions

- Electronic traverse for level winding of product onto reel

- Two secondary operator stations located on the face of the lift arms with functions to control all lift arm positioning and e-stop

- One set of standard case hardened pintles and drive pin

- Uhing traverse system available

Heavy Duty Specifications

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.