Products

- — Bow Cablers

- — Data Cabler

- — Data Group Twinner

- — Backtwist Twinner

- — High Speed Twinner

- — Single Twist Strander

- — Fiber Optic Planetary Strander

- — Aramid Fiber Strander

- — Ribbon Fiber Strander

- — Electrical Planetary Strander

- — Roll Forming Strander System

- — Tubular Strander

- — Drum Stranders & Cablers

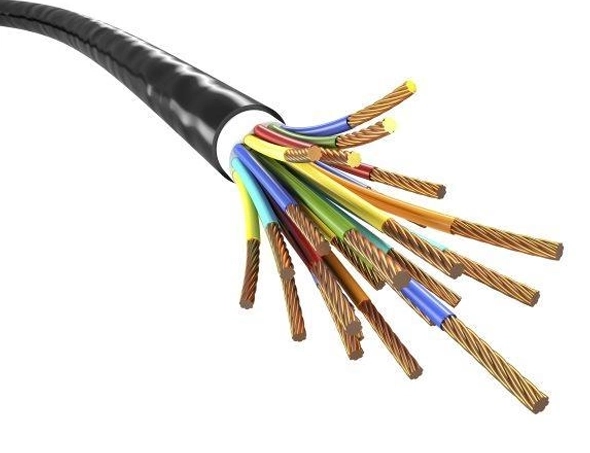

Stranders, Bunchers and Cablers

The Right Solution

Competitively producing cable in today’s manufacturing environment takes the most productive, reliable, and innovative solutions available. With our history forged in wire and cable and the integration of market leader, CEECO, Bartell has been able to create and deliver wire and cable manufacturing solutions that allow its customers to move ahead. From systems that create roll formed trapezoidal shaped conductors allowing for 97% fill factors to high speed tubular stranders Bartell has the right solution for the production of any configuration of copper and aluminum wire and cables.

Our offering includes:

- Planetary & Tubular Stranders

- Double & Single Twist Bunchers

- Roll Form Stranding Systems

- Data Cablers

- Twinners

- Fiber Optic Stranders

WIRE AND CABLE PRODUCTION SYSTEMS

Implementing the “two pass” manufacturing method and combining the backtwist twinners and high speed single twist cabler for assembling 4 to 25 pair backbone LAN cables. Cables produced on this line meet the rigorous demands of categories 5/6/7/7A/8 and 10 Gig UTP requirements for full frequency sweep.

The “Group Twinning and Cabling” line is designed to produce digital communication cables using traditional solid and stranded copper conductors. Cables produced on this line meet the rigorous demands of categories 5/6/7/7A/8* and 10 Gig UPT requirements for full frequency sweep.

The Backtwist Twinner is designed to produce digital communication cables using traditional solid and stranded copper conductors. Pairs produced on this machine meets the rigorous demands of categories 5/6/7/7A/8 and 10 Gig UTP requirements for full frequency sweep.

Bartell supplies a complete range of horizontal twinners to suit requirements for production of Telecom and Data pairs. The twinners are designed to accommodate take up reels with diameters, 400mm (16 in) , 510mm (20 in), 560mm (22 in) and 610mm (24 in).

Single Twist Stranders/Cablers are suitable for stranding, cabling and armouring bare or insulated conductors (with or without taping).

This specific strander has shaft pay off design suitable to assemble fiber optic elements (buffered tubes, ribbons.

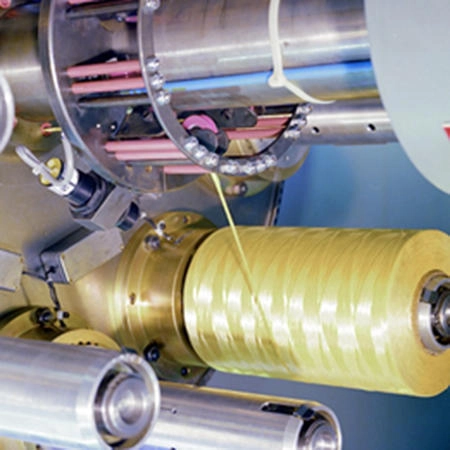

This specific Rigid strander has shaft pay off design suitable to supply Aramid fiber reinforcement materials over the cable.

This specific rigid strander has shaft pay off design suitable to supply fiber optic Ribbon and buffered tube constructions directly into an extrusion line.

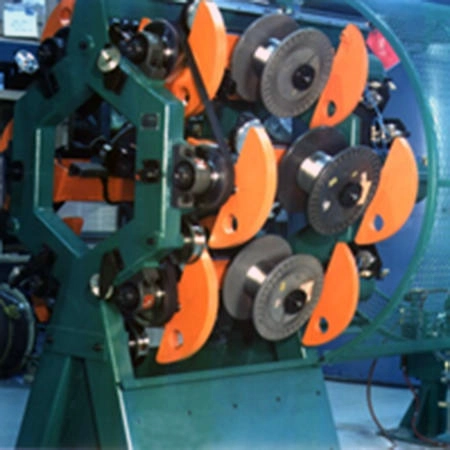

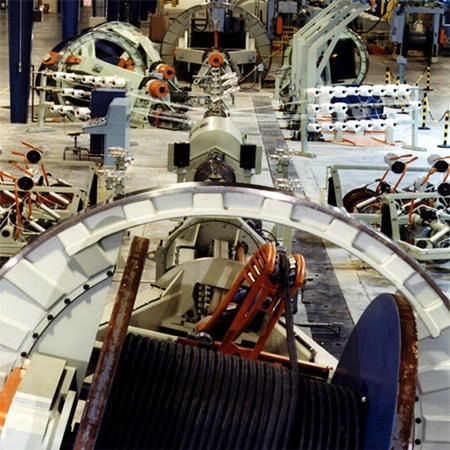

Planetary Stranders/Cablers are cage type machines with backtwist (fixed or variable). They utilizes the principle of stranding/cabling by minimizing the twisting of bar wire/insulated conductors around their own axis.

The Roll Form Stranding process combines the advantages of two highly productive processes, namely: Roll Forming and Single Twist/Double Twist Stranding. These two systems are forged together to create One High Speed Continuous Manufacturing Cell to produce Unilay concentric circular or shaped conductors.

Tubular Stranders/Cablers are suitable for the assembly of bare wires (steel wires, copper and Aluminum ) and insulated conductors into concentric strands or cables. Tubular machine is working with 100% backtwist movement.

The primary components of any Drum Twister lines are; rotating take-ups, rotating pay-offs or, a combination of both. Depending on application they are manufactured in different designs; Closed cradle, Open cradle (Trunnion), Fork type and Vertical type.

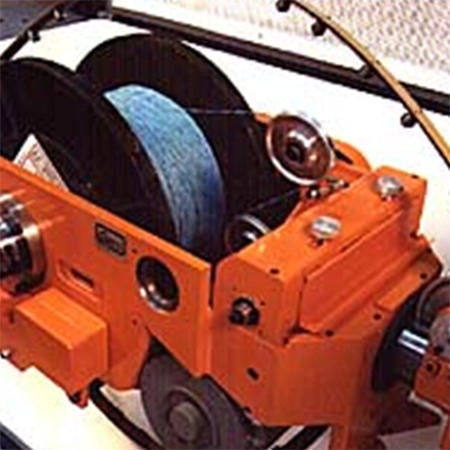

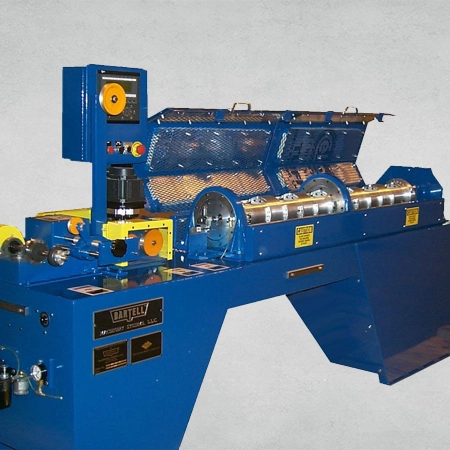

The Bow Cabler is suitable for the assembly of bare and/or insulated conductors. This machine is further used in conjunction with the Tubular Strander/Cabler in reverse concentric-lay Cabling, EM Armouring and OPGW Stranding. The Bow Cabler pay-offs wires successively through a series of rotating bow. Therefore Bow cabler is working with 100% backtwist movement.

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.