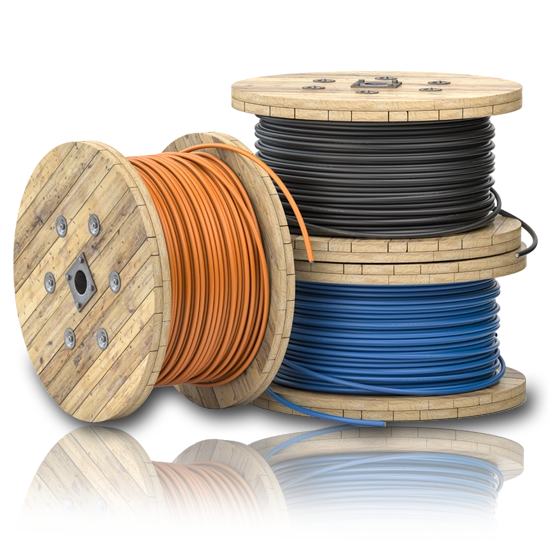

WIRE & CABLE

As a fixture in the global Wire & Cable industry, we are dedicated to delivering premier rotating solutions using our expertise in the shaping, winding, and twisting of wire and cable.

Bartell’s acquisition of Ceeco in 2003 helped to bolster Bartell’s position as a leading solutions provider within the Wire & Cable Industry.

Bartell’s acquisition of Ceeco in 2003 helped to bolster Bartell’s position as a leading solutions provider within the Wire & Cable Industry.

WIRE & CABLE

Bartell’s acquisition of Ceeco in 2003 helped to bolster Bartell’s position as a leading solutions provider within the Wire and Cable Industry

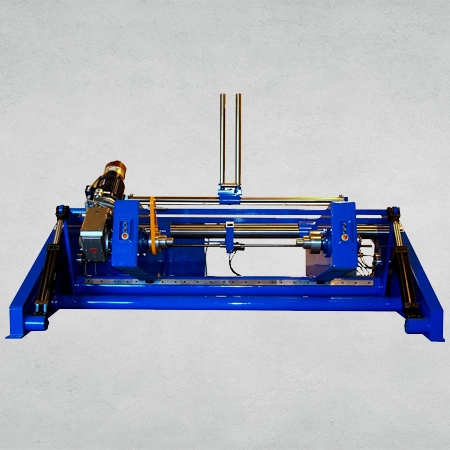

Products

- — Bow Cablers

- — Data Cabler

- — Data Group Twinner

- — Backtwist Twinner

- — High Speed Twinner

- — Single Twist Strander

- — Fiber Optic Planetary Strander

- — Aramid Fiber Strander

- — Ribbon Fiber Strander

- — Electrical Planetary Strander

- — Roll Forming Strander System

- — Tubular Strander

- — Drum Stranders & Cablers

Since its founding, Bartell has been a fixture in the wire and cable industry. Our focus has been to deliver robust rotating solutions based on an expertise of shaping, winding and twisting wire and cable. This focus, along with our acquisition of Ceeco in 2003, has allowed us to develop industry-leading solutions to produce the highest quality products in the most economical, efficient and safe manner possible. From design to installation and service our goal is flawless execution and fostering success through our solutions isn’t a just a job it is a passion.

Strip Armouring represents a low cost solution for the physical protection of energy, instrumentation, coaxial, data and fiber optic cables.

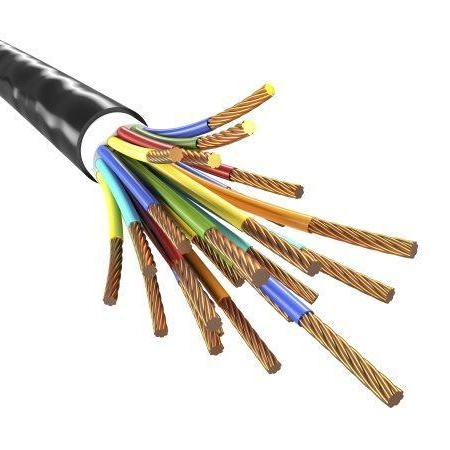

With our history forged in wire and cable and the integration of market leader, CEECO, Bartell has been able to create and deliver wire and cable manufacturing solutions that allow its customers to move ahead. From systems that create roll formed trapezoidal shaped conductors allowing for 97% fill factors to high speed tubular stranders Bartell has the right solution for the production of any configuration of copper and aluminum wire and cables.

Bartell offers a wide range of pay-offs and take-ups to support any application in the production of power cable, steel wire rope, telecommunication cables or any environment where continuous production is desired.

Industries

As our world continues to grow wire and cables play a key role in the in our ability to transmit and distribute electricity throughout the world’s homes, buildings and power grids. From non-metallic sheathed cable (NM) to high voltage aluminum cable Bartell provides manufactures with the equipment and technologies they need to bring consumers the highest quality, best performing cables.

As the demand for high data and communication rates continues to drive cable performance specifications the manufacturing process only gets more critical. Bartell has continuously developed productions systems for both copper and fiber optic cables that allow manufactures to stay ahead by producing the highest performing cables. Through process knowledge, expertise in rotating solutions and our drive to provide our partners the very best in production solutions we continue to push the limits of the possible.

With the continued development of both traditional and renewable energy sources in offshore environments subsea and umbilical cables for power and communication are becoming ever more important. Designed to operate in harsh subsea environments for many years the cables provide the critical link to the operation, control and delivery of energy resources. Bartell has developed a strong record in the design, development and delivery of highly engineered systems for the manufacturing of a diverse range of subsea cable solutions. We deliver turnkey systems that are specifically engineered and manufactured to meet the high standards for cables in subsea applications.

With the rapid the development of technology the needs for smaller wire construction is ever more critical and the challenges in manufacturing these configurations are growing. Through advanced technologies such as tension control and high productivity stranding systems Bartell empowers manufactures to deliver the wire solutions that are driving the technologies of tomorrow.

Financing Available!

See all the ways we can help your business grow for generations to come. Visit our Financing section to see all of our latest programs.